Abstract

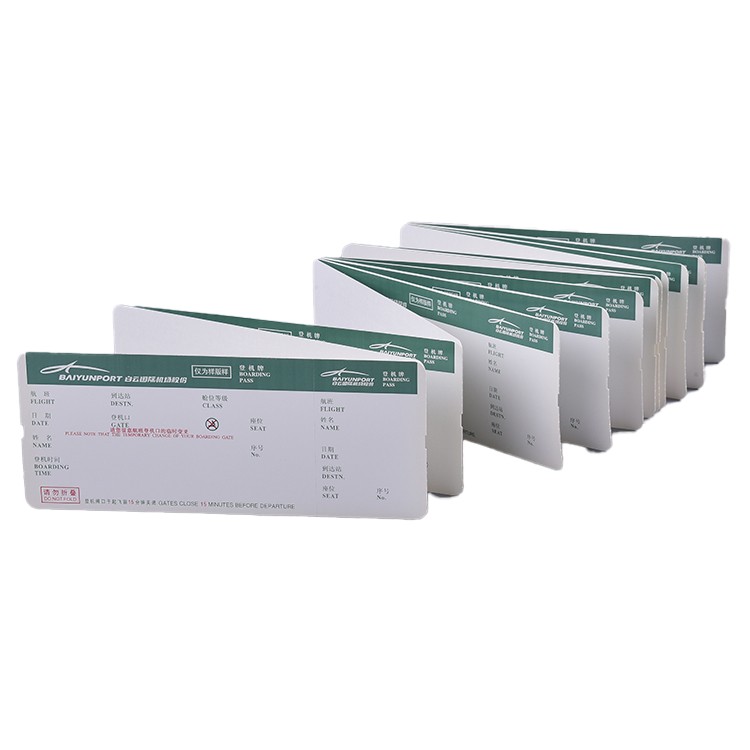

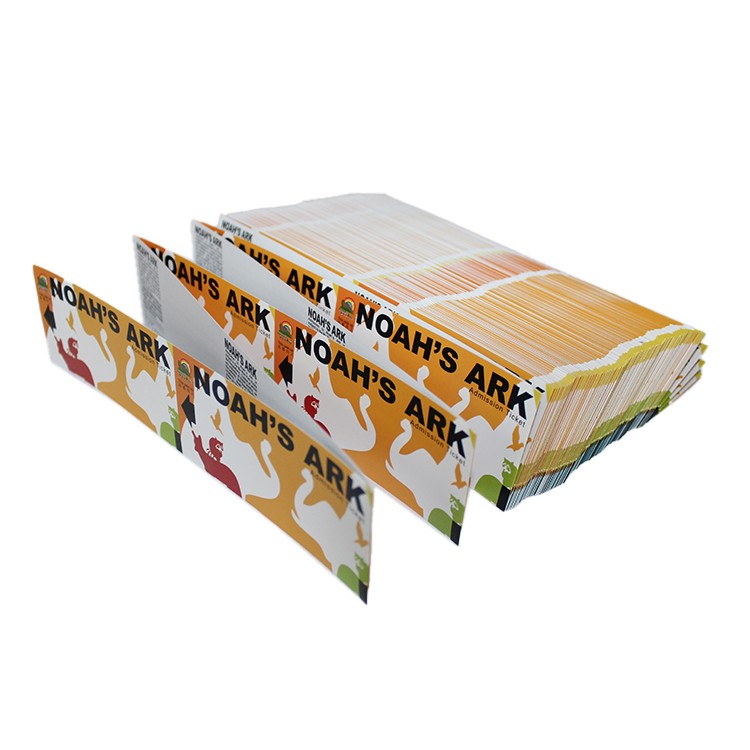

A Ticket Label looks simple—until it fails at the exact moment you need it to work. Smudged barcodes, peeling corners, jammed printers, or labels that won’t stick to cold, dusty, or curved surfaces can quietly turn into long lines, refund disputes, inventory confusion, and compliance headaches.

This guide breaks down what actually matters when choosing a Ticket Label: material, adhesive, print method, finishing, and anti-tamper features—plus a practical checklist you can use before placing a bulk order. You’ll also see common pain points (and how to avoid them), a comparison table, and an FAQ for quick decision-making.

Table of Contents

Quick Outline

- Start with the moment the label must be scanned, verified, or audited.

- Choose the right substrate and adhesive for your environment.

- Match print technology to speed, clarity, and longevity.

- Add security features only where they reduce real risk.

- Test with your actual surfaces, temperatures, and handling routines.

The pain points a Ticket Label should solve

Buyers usually come looking for a Ticket Label after something goes wrong. The “wrong” can look small, but it tends to ripple across operations. Here are the most common pain points—and what to demand from the label design.

- Scanning failures: barcode/QR codes blur, smear, or lose contrast, creating delays and manual overrides.

- Poor adhesion: edges lift, labels fall off, or adhesive leaves residue that causes rework.

- Environmental mismatch: labels crack in cold rooms, fade in sunlight, or wrinkle under humidity.

- Counterfeit risk: tickets are duplicated, swapped, or re-applied without clear evidence of tampering.

- Printer headaches: rolls curl, liners tear, or labels jam—slowing teams and increasing waste.

- Data errors: variable information (seat, batch, serial, date) misprints or shifts out of position.

A well-chosen Ticket Label is basically a tiny system: it carries data, survives handling, and communicates trust to both staff and customers. When it’s specified correctly, you reduce exceptions, speed up throughput, and protect revenue.

Where Ticket Labels fail most often

Labels don’t fail on a desk. They fail in motion—during rush hours, under heat lamps, inside freezers, on curved containers, or in the hands of people who are moving fast. Consider these high-risk situations:

- High-friction handling: tickets rubbing against wallets, lanyards, pockets, or conveyor belts.

- Low temperatures: cold-chain logistics, refrigerated storage, or winter outdoor events.

- Humidity & condensation: damp venues, wet packaging, or fast temperature changes.

- Direct sunlight: outdoor festivals, transportation labels, and storefront exposure.

- Chemical contact: cleaning agents, oils, cosmetics, or industrial solvents.

- Security-sensitive entry: situations where swapping or reusing a label creates real losses.

What a high-performance Ticket Label is made of

You don’t have to be a materials engineer to buy labels well—but you do need to control a few key variables. Think of every Ticket Label as a stack of decisions:

- Face stock: paper, synthetic (PP/PET), or specialty films chosen for strength and print clarity.

- Adhesive: permanent, removable, freezer-grade, high-tack, or residue-free formulas.

- Liner: the backing that affects dispensing speed, roll stability, and machine compatibility.

- Print method: thermal direct, thermal transfer, digital, flexo, or offset for different durability needs.

- Finishing: matte/gloss lamination, varnish, UV coating, scratch resistance, and edge protection.

- Security features: VOID patterns, destructible materials, holograms, microtext, serial numbers.

If you need short lifecycle labels (fast, cost-effective), thermal direct can be great—until heat or friction becomes a factor. If you need labels to last, thermal transfer or coated stocks often win. If brand presentation matters (premium tickets or product-facing labels), digital + finishing can deliver sharper visuals and stronger wear resistance.

Where Guang Dong-Hong Kong (GZ) Smart Printing Co., LTD. adds value: practical specification support.

Many label problems come from mismatched specs—not “bad printing.” A supplier that asks about surfaces, temperatures, handling, scan distance, and security risk can save you from reorders and last-minute fixes.

Material & finish comparison table

Use this table as a quick filter. It won’t replace testing, but it will help you avoid obvious mismatches when selecting a Ticket Label for your environment.

| Option | Best for | Strengths | Watch-outs |

|---|---|---|---|

| Coated Paper | Indoor events, short-term use, high volume | Cost-effective, crisp printing, easy scanning | Less water/scratch resistance; can tear under friction |

| Thermal Paper | Fast printing and short lifecycle labels | No ribbon needed; quick production and operations | Heat and sunlight can darken/fade; friction may reduce readability |

| PP Film | Moisture-prone handling and flexible surfaces | Water resistance; good durability; clean appearance | May need stronger adhesive for textured/low-energy plastics |

| PET Film | High durability, heat resistance, long-term ID | Excellent stability; strong chemical resistance | Typically higher cost; may be “too permanent” for some workflows |

| Destructible / Tamper-Evident | Anti-swap entry, warranty seals, security tickets | Shows removal attempts; reduces reuse and fraud | Not always needed; can complicate removal or returns |

| Lamination / UV Coating | High friction, outdoor exposure, premium look | Scratch resistance; better water and fade protection | Adds cost; must confirm scan contrast remains strong |

A buyer’s checklist before you approve production

This is the checklist that prevents expensive surprises. If your supplier can answer these clearly, you’re already ahead. If they can’t, you’re gambling with the next shipment of Ticket Label rolls.

- Surface reality: What exactly will the label stick to (paper, plastic, metal, fabric, curved bottles, rough cartons)?

- Temperature window: Lowest/highest temperature from application to end-use (including transport and storage).

- Handling profile: Will it be rubbed, folded, exposed to sweat, or cleaned with chemicals?

- Scan conditions: Scan distance, lighting, scanner type, and whether staff wear gloves or move fast.

- Data type: Static design vs. variable data (serials, QR, batch, seat numbers, dates) and required accuracy.

- Security need: Is tamper evidence needed, or is it a “nice-to-have” that adds cost without value?

- Roll specs: Core size, roll diameter, winding direction, gap, and printer compatibility.

- Finish preference: Matte vs. gloss, scratch resistance, and whether coatings affect scanning performance.

How customization works in real life

Custom labels shouldn’t feel mysterious. A reliable workflow typically follows a few predictable steps, and each step is there to protect you from misprints, scanning trouble, or adhesion failures.

- Requirement mapping: you define environment, surface, lifecycle, security risk, and scan process.

- Material selection: face stock + adhesive + liner chosen for your conditions.

- Artwork & data planning: layout, quiet zones for codes, variable fields, and human-readable backups.

- Sampling: prototypes for scan tests, rub tests, temperature exposure, and peel performance.

- Production control: color consistency (if needed), die-cut accuracy, roll tension, and packaging protection.

- Delivery fit: rolls or sheets packaged to avoid curling, moisture absorption, or edge damage.

The goal is simple: your Ticket Label should behave predictably across the entire lifecycle—printing, application, handling, scanning, and audit. If you’re buying for multiple locations, this consistency becomes even more valuable because it reduces training issues and “one branch does it differently” exceptions.

FAQ

How many times should a Ticket Label be scanned without degrading?

It depends on material, print method, and finishing. If you expect repeated scanning, prioritize high-contrast codes, abrasion resistance, and coatings that protect ink or thermal layers. For multi-day events or logistics workflows, testing under real handling is the fastest way to confirm durability.

What’s the difference between removable and permanent adhesives for Ticket Labels?

Removable adhesives allow clean removal (useful for temporary ID or short-term tracking). Permanent adhesives resist peeling and are better for long lifecycle or high-risk environments. If you need both security and clean removal, consider tamper-evident designs that show removal attempts while still controlling residue.

Will lamination affect barcode or QR scanning?

It can—usually in two ways: glare (with glossy finishes) and reduced contrast if the coating darkens printed areas. Matte finishes often scan more consistently in bright environments. The safest approach is to scan-test the finished sample using your actual scanners and lighting.

When do I need a tamper-evident Ticket Label?

Use tamper-evident features when swapping, reuse, or removal creates measurable loss—like access control, warranty seals, or high-value inventory tracking. If the risk is low, you may be better served by improving scan reliability and adhesion rather than paying for security features you won’t use.

What info should I provide to avoid rework and delays?

Provide surface type, temperature range, expected handling, desired lifecycle, roll specs (core size/diameter), printer model if relevant, and whether you need variable data like serial numbers. The clearer the inputs, the faster you’ll get a sample that behaves like the final production.

Next steps

The best Ticket Label is the one that disappears into your workflow: it sticks, scans, survives handling, and quietly prevents costly exceptions. If you’re comparing options, start with your “failure moment,” then match material, adhesive, and finishing to the environment—before you commit to volume production.

If you want a Ticket Label that’s tailored to your surfaces, temperatures, scan process, and security needs, work with a supplier that treats specification as problem-solving—not guesswork. Guang Dong-Hong Kong (GZ) Smart Printing Co., LTD. can help you map requirements, produce test samples, and move into stable, repeatable production.

Ready to reduce scan failures, peeling, and reprints? contact us with your use case and basic specs, and let’s build a label solution you won’t have to think about again.